Manufacturing is a critical sector of the global economy, and the way payments are made within this industry constantly evolves. In order to stay ahead of the curve, it’s important for businesses in this space to understand the latest trends in B2B payments. In this brief guide, we will look at some of the most important aspects of Manufacturing payments and how they are changing with the advent of digital transformation.

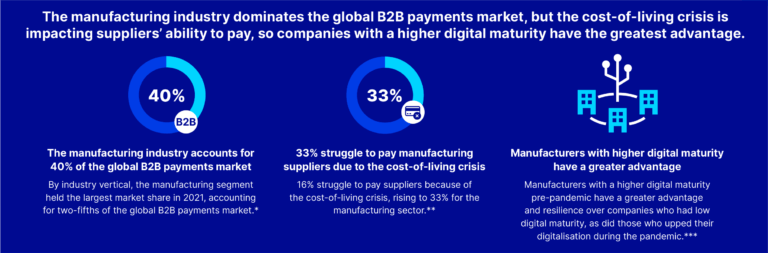

The manufacturing industry is responsible for a large portion of the global B2B payments market. This is because manufacturing is often a large and complex process requiring many suppliers. Manufacturers often use specialized software to keep track of all the different payments. This software helps to automate the process and keep track of all the different invoices. By using this software, manufacturers can save time and money on their B2B payments.

According to a recent survey, one in three small businesses in the UK are struggling to pay their manufacturing suppliers due to the cost-of-living crisis. This is a worrying trend, as the manufacturing sector is a key driver of the UK economy.

The cost-of-living crisis puts pressure on businesses of all sizes, but small businesses are particularly vulnerable. Rising costs for energy, fuel and raw materials are putting a strain on margins, and many small businesses are being forced to increase prices to stay afloat.

Manufacturers with a higher digital maturity pre-pandemic have a greater advantage and resilience over companies with low digital maturity, as did those who upped their digitalization during the pandemic.

For manufacturers, having a higher degree of digital maturity means taking full advantage of Industry 4.0 technologies to optimize their processes and products. This gives them a competitive edge in today’s market. Many manufacturers have invested in digital transformation for years, but the pandemic has accelerated the pace for many.

Companies with low digital maturity going into the pandemic have struggled more to adapt and keep up with the changes. The pandemic has forced them to invest in digital transformation much faster than they were comfortable with or prepared for. As a result, these companies have often lagged behind their more digitally mature counterparts.

The pandemic has also been an opportunity for companies to increase their digital maturity. Many companies have invested in new technologies and processes during the pandemic to keep up with the changes. As a result, these companies have often come out of the pandemic stronger and more digitally mature than before.